3D BioFibR introduces new collagen fibers to enhance 3D printing

3D BioFibR, a Canadian tissue engineering company, is launching two new collagen fiber products, μCollaFibR and CollaFibR 3D scaffold, to enhance 3D bioprinting.

These new off-the-shelf products are made using 3D BioFibR’s new proprietary dry-spinning technology, which can create collagen fibers at commercial scales. The new products offer advantages in tissue engineering and tissue-culture applications.

From a strength, diameter, and quality perspective, 3D BioFibR claims that their products are “best in class,” accurately recreating the natural appearance, structure, and function of collagen fibers. The dry-spinning process is claimed to be up to 3,600x quicker than the competition. The collagen fibers can be used for an increasing number of biomedical applications in the tissue-engineering market.

“3D bioprinting is the future of regenerative medicine and it’s exciting to offer μCollaFibR to enhance the capabilities in 3D bioprinting. We all want to imagine a future where doctors could just print a kidney, using cells from the patient, instead of having to find a donor match,” commented 3D BioFibR CEO Kevin Sullivan. “Our collagen fibers represent a significant improvement over existing scaffolds used in 3D bioprinting, moving the field closer to this reality.”

Both μCollaFibR and CollaFibR 3D scaffold products are available to purchase now from the 3D BioFibR online store.

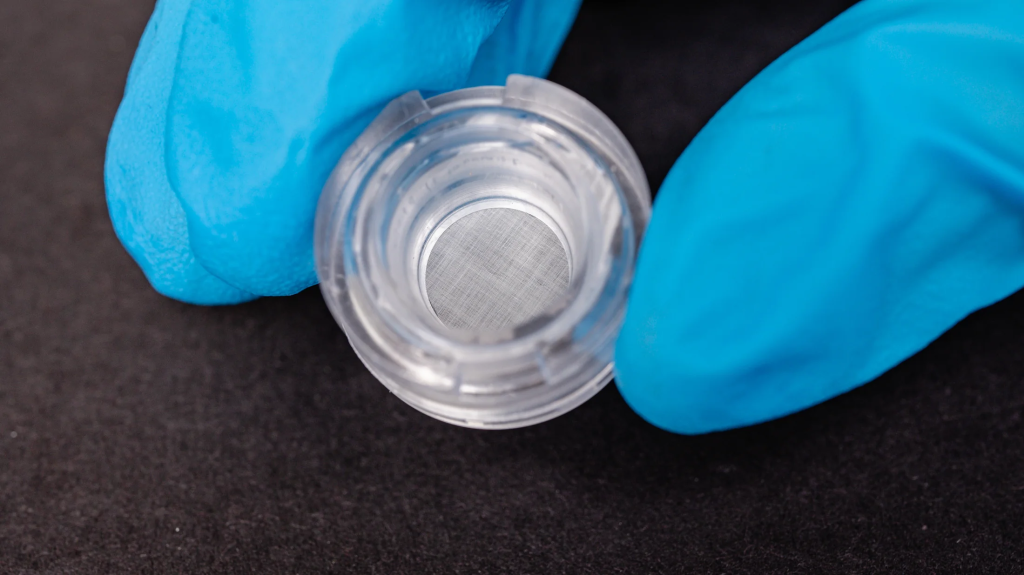

μCollaFibR and CollaFibR 3D scaffold

In biomedical research, collagen is commonly used in monomeric form. Researchers usually use digested (individual) proteins. While monomeric collagen is useful for many purposes, increasing efforts are being made to reassemble individual proteins into fibers which more accurately represent the collagen fibers of the human body.

μCollaFibR (pronounced micro-CollaFubR) is a bioinkn additive for laboratory 3D bioprinting of tissue and organ models. This product works by mimicking the body’s cellular scaffolds, acting like a biological rebar in bioinks used to 3D print living tissue.

Once added to bioinks, μCollaFibR enhances the mechanical durability of 3D printed tissue, allowing multiple cell layers to 3D printed layer-by-layer. This allows for the creation of highly functional organ and tissue models.

CollaFibR is a scaffold designed for 3D cells cultures. This allows researchers to study cell reactions in an environment that is more physiologically realistic than 2D cultures. This offering has the advantage that it is made from GMP type 1 collagen. This creates a collagen fiber matrix that is consistent and mimics the biochemical properties of natural cell environments.

“Our CollaFibR scaffold allows cells to grow and interact with the surrounding cellular scaffold in 3D, making it ideal for creating realistic tissue constructs for laboratory testing of new drugs and tissue models,” explained Sullivan. “Plus, our standard well plate dimensions are compatible with automated equipment for high throughput compound screening and advanced microscopy.”

3D Bioprinting: The future of 3D printing

3D bioprinting has become a rapidly growing industry within the 3D printing sector. Researchers at UMC Utrecht, for example, recently announced three innovations in volumetric printing. These new innovations are related to the creation biologically functional areas in 3D-printed cells, the use granular gels for optimizing 3D-bioprinted cells, and combining volumetric printing with melt electrowriting for 3D printing blood vessels. Scientists hope that these new developments will expand the clinical uses of 3D Bioprinting.

3D Systems, on the other hand, announced in February this year plans for a RegenerativeTissueProgram (RPT). This strategic initiative is aimed at developing and commercializing bioprinting of human tissue. 3D Systems is reportedly able to design and 3D-print bio-integrative scaffolds which match the unique anatomy of a patient. A key application is the 3D printing of patient-specific regenerative tissue for breasts.

Subscribe to the Newsletter 3D Printing Industry News You can also follow us on Twitter to stay up-to-date with the latest 3D print news. Follow us on Twitter. TwitterEnjoy our Facebook Subscribe to our page and receive updates 3D Printing Industry YouTube Access more exclusive content by channel.

Do you want to work in the additive manufacturing sector? You can visit the website to learn more about additive manufacturing. Jobs in 3D printing View a variety of roles available and start your career.

Featured image shows μCollaFibR by 3D BioFibR. Photo by 3D BioFibR.